TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

Metal cutting can consist of mechanical and thermal cutting. Plasma cutting is a thermal cutting method where ionized gas is used for cutting materials. This is a widely used plasma cutting method that can handle thick metal plates and sheet metal

Plasma is an electrically conductive ionized gas. Some atoms are missing electrons and there are also free electrons floating around. The gas can be transformed into plasma by subjecting it to intense heat. Plasma is often called ionized gas.

Plasma cutting is a thermal cutting method. It uses heat to melt the metal instead of mechanically cutting it. Plasma cutters use compressed air or other gases such as nitrogen. Plasma is created by the ionization of these gases. The compressed gases come into contact with an electrode, and then ionize to create more pressure. After pressure builds up, a stream of plasma is pushed to the cutting head.

The cutting tip is designed to constrict the flow creating a stream of plasma. The plasma then comes in contact with the workpiece. Because plasma is electrically conductive, the workpiece is grounded through the cutting table. The high temperature plasma melts the metal. High speed gases blow away the molten debris. Plasma cutting is a fast method for metal cutting. It can be best suited for smaller workpieces.

Waterjet cutting technology has been used since the 18th century to excavate minerals in coal mines and find gold beneath rock. It evolved to commercial use. Soon water jet cutting tools were used in the aerospace industry. In the early 1970s, this technology was used for manufacturing paper tubes. By the 1980s, the first abrasive water pressure cutting machines were in place.

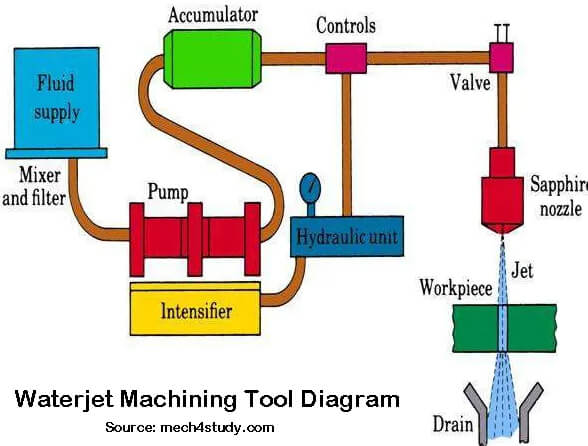

Waterjet cutting is a sheet metal fabrication process. It can cut nearly any type of material, both soft and hard. The waterjet cutting process uses pressurized pumps to deliver high pressure jets of water that can cut materials. The jets of water can reach three times the speed of sound. This creates a destructive force that can cut through nearly any material. This is a viable metal cutting method for thermally sensitive or thicker materials.

Waterjet cutting machines consists of a work area, controller, a high pressure pump, and an abrasive delivery system.

Work table – The workpieces are placed here. The cutting table must be durable enough to handle the weight of heavy metal plates, and not mark or scratch those materials. Table can be made of a variety of metals such as steel, aluminum, or a mixture of metals.

Controller & Drive – The cutting machine motion is controlled and commanded here. Typically these cutting machines have PC based controllers, with a wide range of functions programmed by software integrated into the controller and drive system.

High pressure pump – The pump pressurizes the water to anywhere from 40-50PSE all the way up to 90PSI or higher. High pressure waterjet cutting tool pumps come in variety of models and features.

There are multiple benefits to waterjet cutting. Most fabrication shops have water jet cutters. They are a very versatile cutting tool that can cut to extreme precision and produce rounded edges.

Continuous Jet – The characteristics of this type can be divided into liquid jet, liquid solid jet, liquid-gas-solid jet. The waterjet pressure can be divided into low-pressure jet, high-pressure jet, and ultra-high pressure jet. The media around the jet can be divided into submerged jet and non-submerged jet. And the jet can be divided into atomization jet, modeling jet, vacuum jet, fine jet, and cylindrical jet.

Pulsed Jet – This is a discontinuous jet. It is produced in a several ways: sudden release of shaped energy, pressure extrusion, or flow regulation also known as water hammer.

Cavitating Jet – This is a kind of continuous jet that produces cavitating bubbles in the jet. The bubbles are drawn into the jet and grow until they are close to the cutting surface, where they break due to blockage. During this process, high pressure and micro jet are produced. The target stress area is higher than the tensile strength of most materials, making the cut.

As a creator of Automation Tooling Systems, we also utilize plasma & waterjet cutters that attach to automated robotic arms. Our robotic arms are highly capable and programmable, allowing the onboard computer to carry out multiple tasks at once while to changes in the production process. Having the ability to use either cutting process on robotic arms is another example of our versatile metal cutting services.

Below is just a short list of the materials we can cut using waterjet or plasma cutters.

To learn more about our Plasma & Waterjet cutting capabilities, contact Gable Manufacturing today. Our specialists will answer your questions and offer a solution that meets your exact specifications.