TOOLING FIXTURES

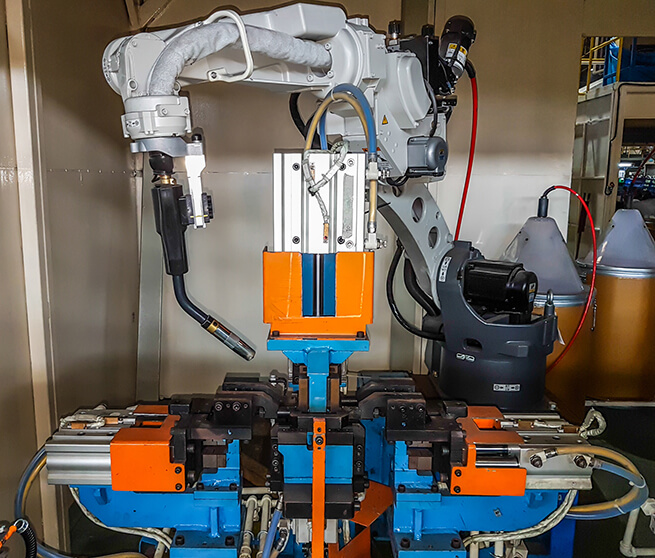

WELDING SYSTEMS

SYSTEM INTEGRATION

Nut welding is a projection welding process to weld nuts on to a metal object. It’s a projection weld because the nut typically has a full or partial ring projection or the corner edges are formed into projections. Nut welding is common in the automotive and appliance industries. These nuts offer an assembly point for bolts, screws and other fasteners.

Resistance or projection welding is typically used for nut welding. Projection welding of a nut involves three steps. First, the projection is in contact with the mating sheet. Second, the current starts to heat the projection to the welding temperature. Third, the electrode force causes the heated projection to rapidly collapse and fusion occurs. The current is generally less than required to produce the spot weld. The projection will rapidly heat, and the excessive current will melt it and result in expulsion. The current must be high enough to create fusion before the projection has completely collapsed.

Stud welding can be called drawn arc welding. Stud welding is used for attaching fasteners to metal sheets. With weld studs, welds of superior strength can be formed. There are a variety of stud welding applications available. Stud welding is a faster and more efficient process for attaching fasteners, and can be used for a range of processes to achieve strong attachments. Stud welders can also be used on a variety of metals, allowing for greater industry applications.

Stud Welding Process

A metal stud is joined to a metal piece by heating both parts with an arc. What differentiates stud welding from other welding is that the fastener is attached to the workstation without marring the other side. Arc stud welding provides reliable fastening for a wide range of applications. Nearly any size or configuration of a metal stud can be welded to a workpiece. Arc stud welding also allows for strong, one sided welds on base metals with a thickness of 0.048” or greater. Arc stud welding uses a DC power supply to create the arc, a welding tool, and metal fasteners.

There are four essential pieces of equipment for Stud Welding:

The single sided nature of stud welding allows for a variety of uses such as: