TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

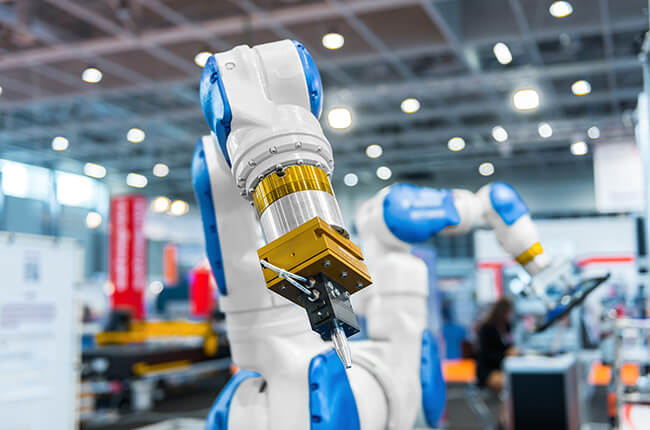

A fundamental aspect of Automation Tooling Systems, End-of-Arm Tooling is centered on the piece of equipment attached to the end of a robotic arm. The affixed component, also known as an end effector, allows the robot to perform a variety of specific functions and services.

These include: random bin picking, pick-and-place, welding, small parts handling, and parts inspection. Without an end effector, most robotic arms are essentially useless. The talented and dedicated engineers and designers at Gable Manufacturing have built countless end effectors for a variety of applications, including but not limited to:

Choosing the right EOAT (end-of-arm tooling) equipment is critical to creating an efficient and optimized workflow within automated robotic work cells. Even reducing seconds of time in the production process can result in saving multiple hours and thousands in rework costs. By implementing custom built end effectors such as grippers, the precision in parts handling is vastly improved. Each part will be carefully placed exactly where it needs to be, every time. By utilizing the proper end effector in tandem with a reliable automated system, production speed and consistency vastly improves. Some examples of EOATs are explained in detail below.

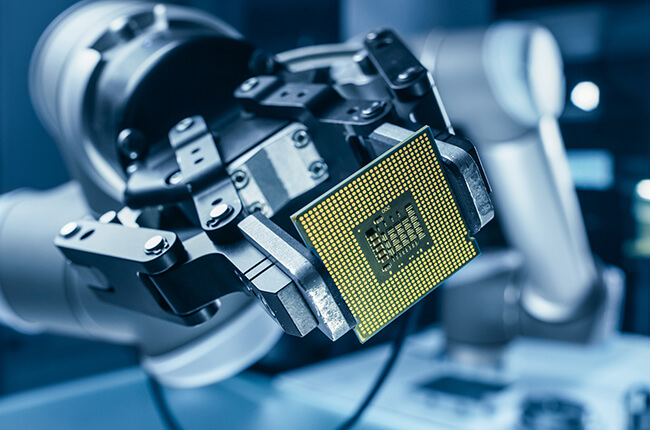

Grippers allow robotic arms to pick up and interact with objects. Grippers are most effective in pick-and-place operations, but they can also be used to tend to machines and assemble components. Grippers come in a variety of configurations, including ones with two and six fingers. Fingered grippers are useful in applications where standard grippers or vacuum cups are inadequate, specifically when a part requires precise and specific manipulation.

Vacuum cup systems are used for load-bearing operations. Vacuum cups are another very common type of end effector. They are normally used to move large and heavy components from one place to another. For example, when a large pane of glass needs to be moved down the assembly line, vacuum cups are almost always employed to safely move the glass. Our vacuum cup systems are highly durable and made to provide tight and reliable seals to prevent components from being dropped.

Quick changers automatically facilitate rapid and efficient transition from one end effector to another. Our quick changers feature both electric and pneumatic interfaces, depending on the EOAT being mounted. One system is able to connect with multiple tool sides, making it a very cost-effective option. Since the automatic change can be performed in seconds, productivity is increased dramatically over manual operation.

Robotic arms can also have a variety of welders affixed to them. End effectors with welding torches are often used for spot welding and arc welding. The ability to automate the welding process offers a significant advantage in that high-quality welds can be produced far more rapidly than manual welding. A variety of industries often use automated systems for welding. MIG, TIG, Laser, and other forms of welding can all be accomplished through the use robotic arms.

Determining the specific task you require the robotic arm to perform is vital. Once this is done, the different types of EOATs that are able to perform this task are examined. There can be numerous ways to perform a given task with different end effectors. So other factors such as cost and complexity re considered. These factors must be taken into consideration to choose the appropriate EOAT for your needs.

Contact our experienced team of engineers at Gable Manufacturing today. We’ll help you evaluate your EOAT needs. Our knowledgeable and skilled staff will assist you in choosing the right end effector for your needs. We also provide custom-made components and design services. Let Gable Manufacturing be your one-stop location for all your robotic End-of-Arm Tooling and custom end effector-building needs.