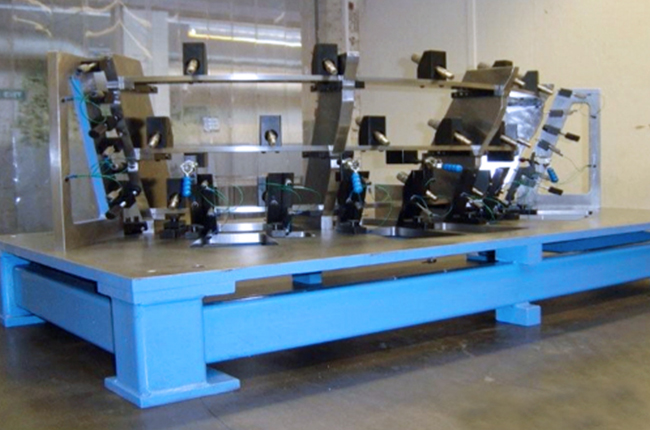

TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

Gable Manufacturing can design custom automated workcells and fixtures for your applications. We design and build automated equipment ranging from simple fixtures to larger assembly line modules. Assembly Workcells and Fixtures can shorten cycle times by allowing for multiple tasks to be performed in a short amount of time, while accurately performing multiple tasks.

The engineering and manufacturing teams at Gable Manufacturing can create customized assembly workcells and fixtures that meet all of your specifications and production needs.

Assembly Workcells are a group of workstations, equipment or machines arranged so parts can be assembled progressively from one station to the next. This eliminates having to wait for a batch to be completed or handling between operations. Workcells can be devoted to a process, a subcomponent, or an entire product. Workcells are designed to improve efficiency and eliminate wasted motion and time.

Gable Manufacturing takes the time to understand your work processes and goals. We plan a workcell design that will meet your needs. The flow of any workcell includes people, equipment and materials. Typical goals are to reduce work space, improve production, provide predictable and quality production, and improve cross training. Gable Manufacturing understands how to design effective workcells to turn raw materials into finished products, create greater efficiency, reduce waste and increase overall manufacturing performance.

According to Six Sigma Material guidelines, these are the questions to consider for cellular flow:

Assembly fixtures can speed up the production process of manufacturing identical parts. We can provide a quality assembly fixture to help your business optimize the machining process. We examine your needs and operating tools to allow for the assembly fixtures to be arranged and set before assembly. Once the assembly fixtures have been set up, this will increase production speed and quality for your operations.

We can provide you with a wide range of assembly fixtures for your manufacturing situations. Whether needing a short run or the manufacturing of a prototype, Gable Manufacturing can provide an assembly fixtures solution.

Assembly Fixtures can be made for a wide variety of needs ranging from models for indexing, tapping and boring, turning, welding and grinding.

Common types of assembly fixtures: Vacuum Clamping, Magnetic Clamping, Vision Fixture

Individual parts include: Hold-down Clamps, Vises, Three-jaw chucks, Tension Spring