TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

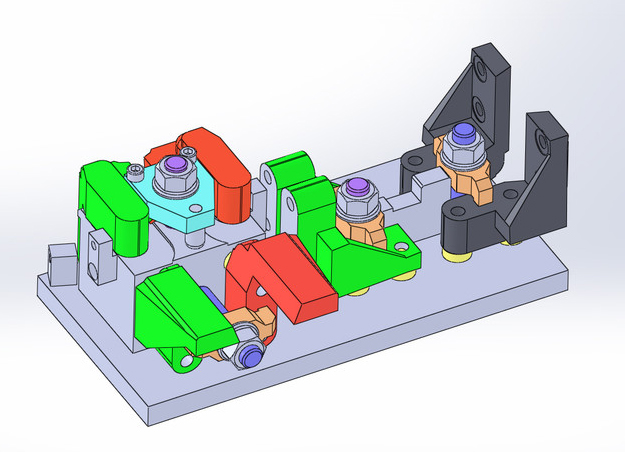

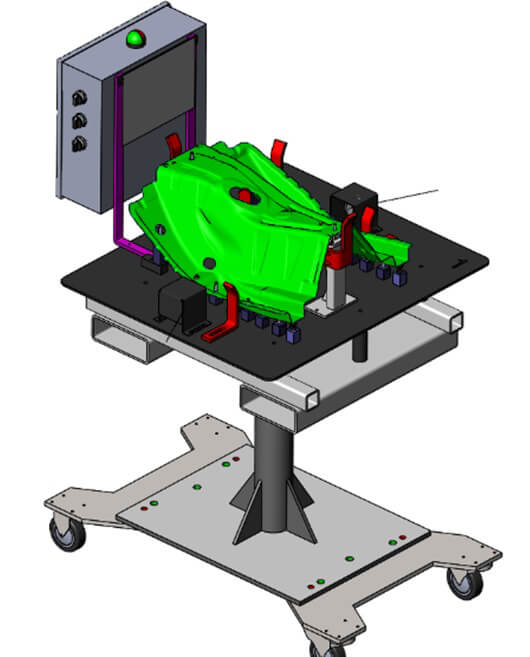

At Gable Manufacturing, we design and build Poka-Yoke Fixtures for a variety of applications. “Poka-Yoke” is a term which translates to “mistake-proofing.” This means that the potential to make errors in manufacturing is specifically engineered out of the process to ensure proper alignment and fitment of various parts. This can be as simple as designing the fixture to very tight tolerances to ensure a workpiece doesn’t move, or installing pins onto the fixture to make sure the workpiece can only be inserted in one specific way.

Poka-Yoke Fixtures normally use clamps to hold an object in place by one or more directions of translation or rotation. By preventing the workpiece from becoming incorrectly oriented, the Poka-Yoke principle is now incorporated. In the event an assembly worker begins aligning the workpiece incorrectly, the Poka-Yoke fixture prevents said workpiece from fitting into place. Thus, the worker will notice the error and correctly realign the workpiece. The workflow is now improved as fewer decisions in regards to workpiece handling need to be considered by the worker.

This design philosophy is implemented not only in our fixtures, but also in our day-to-day operations at Gable Manufacturing. Contact our experts today and see how our Poka-Yoke Fixtures and implementation can help your robotic automation needs.