TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

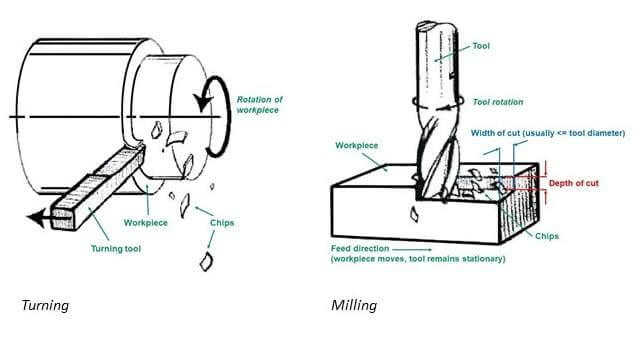

CNC turning is a subtractive manufacturing process. Pieces of material are rotated as a machine tool is fed to the piece, removing material to create a finished piece. CNC Turning is primarily used to manufacture parts that are cylindrical in nature.

Although a variety of materials can be used with CNC turning, the most common are metal alloys like aluminum.

CNC Turning Machines are also referred to as CNC lathe machines. Machine tools rotate a bar of material, allowing the cutting tool to remove material from the bar until the desired product remains.

The material itself is secured to, and rotated by, the main spindle, while the cutting tool can be moved along multiple axes. The typical parts created by a CNC lathe are often cylindrical, or symmetrical around an axis.

Gable Manufacturing offers high precision CNC turning services for a wide range of metals. Using automatic bar-fed CNC lathes, we can create one-piece CNC turned parts quickly and to high tolerances. CNC lathes can be used for turning, thread-cutting, boring, reaming and chamfering. These versatile machines allow for multi-axis movement, single set-up, and one-pass manufacturing. Computer controlled CNC lathes can produce products with exceptional accuracy with operator error eliminated.

CNC machines consist of the following parts:

CNC machining can be superior to manual machining for a number of reasons:

The CNC turning process involves material secured to a spindle within a CNC machine. A cutting tool moving in linear fashion removes undesired material until the finished component is left.

CNC turning centers are computer numerically controlled machines. They may have 3, 4, or 5 axes. They have a variety of cutting capabilities, including milling, drilling, tapping, and turning. These machines have an enclosed setup to ensure cut material, coolant, and components remain within the machine.

There are two categories of CNC turning centers, horizontal turning centers and vertical turning centers.

Horizontal turning centers are more commonly used than their vertical counterparts. Vertical CNC turning centers have an advantage for parts that are heavy and short.

Whereas a CNC Machining Center performs a rotating spindle operation, a CNC Turning Center performs a turning type operation.

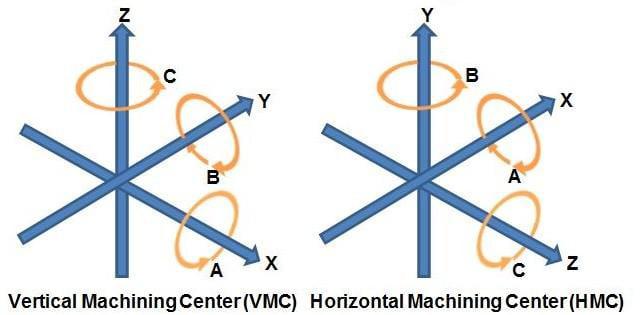

Typically CNC turning centers operate on 5 axes. However, there are some machines that can operate on 6 axes.

Image source: Aldermans Tooling – The What, Why and How of CNC Axis Machining, May 21, 2019

CNC machines consist of the following parts:

We specialize in CNC Milling, used in a variety of industries. Gable Manufacturing’s CNC milling capabilities provide our customers with high quality workmanship. CNC machining can crate intricate part details quickly and efficiently. Our experienced CNC Machining staff is proficient in horizontal, vertical, multi-axis CNC Milling, and CNC Turning and Boring. Whether your part is to consist of simple, flat surfaces or multiple, highly complex cuts, we can handle the job while adhering to extremely tight tolerances. Our CNC milling machines are able to operate along the X, Y, and Z axes, giving us additional flexibility when a customer needs a very specific part made.

CNC Machine Boring expands or refines holes in a workpiece. CNC boring can correct misshapen holes, achieve the precise hole position and precision roundness. CNC Boring is often used as a final process. We provide a variety of CNC boring capabilities. The boring process consists of the workpiece held in place by the chuck. The head of the boring tool is inserted into the pre-drilled hole and begins to scrape away at the wall of the hole. The hole gets larger until the boring tool is finished.

Gable Manufacturing is committed to providing you with the finest CNC Milling and Turning services. Our team is trained to meet and exceed international standards, as well as deliver high quality parts with short lead times. Contact us today!