TOOLING FIXTURES

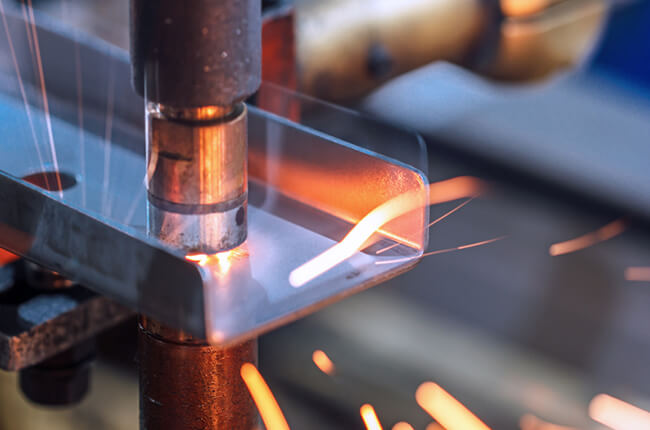

WELDING SYSTEMS

SYSTEM INTEGRATION

Gable Manufacturing designs, builds and maintains fully integrated, turnkey automated spot welding systems. We have a complete selection of resistance welding controls, weld heads, power supplies, weld monitors, and data acquisition equipment. This equipment can be integrated through PC or PLC based motion control systems.

Manufacturers and fabricators rely on a variety of material joining methods. Automated robotic spot welding is a universal method for bonding materials, and provides accuracy, high repeatability and cost reductions.

Many manufacturers see advantages to robotic spot welding including:

The automotive industry first embraced automated spot welding. Automotive factories contain many different types of automated robotic systems. Auto body frames are typically spot welded at the joints with robotic welding systems. Aerospace is another industry benefiting from automated spot welding systems. The airline industry, marine manufacturing and the medicine are other industries using automated robotic spot welding.

Many robotic spot welders are articulated arm or six-axis. These types of robotic welders have the ability to contort themselves around the workpiece. They can reach difficult areas and make difficult welds.

Consistent Welds - Automated robotic spot welding systems perform the same weld, in the same way, each and every time. Six axis robots can have metrics in the sub-millimeter ranges.

Higher Throughput – Robotic welding systems have higher welding speeds. They are faster than manual welders and can keep up a quicker pace day after day.

Cost Reductions – The price of automated robotic systems is primarily in the initial cost of acquisition. The increased productivity of an automated spot welding system will exceed the initial investment over time. This can result in cost reductions and higher profits. The lower cost of robot maintenance can reduce business overhead.

Labor Reliability - With the pool of skilled workers dwindling, automated spot welding systems are a viable and cost effective alternative for most businesses. Automated welding systems are robust and consistent. They can remain in service for over a decade or more with regular preventative maintenance.

Gable Manufacturing can deliver higher efficiencies, energy savings, and reduced costs through our automated robotic spot welding systems.