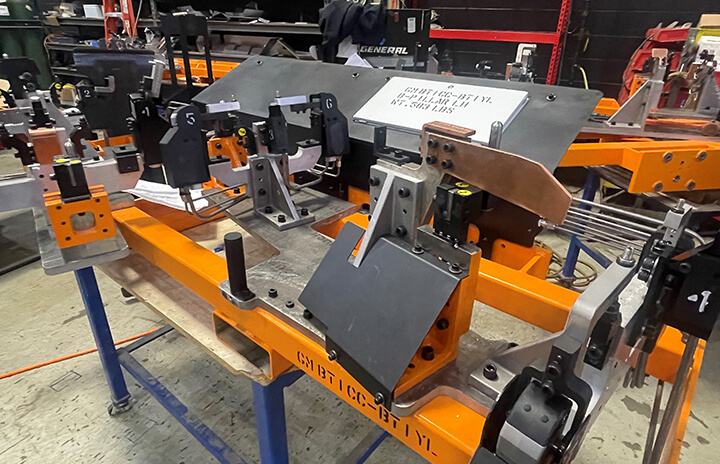

TOOLING FIXTURES

WELDING SYSTEMS

SYSTEM INTEGRATION

Laser cutting technology advances have offered new options: higher power lasers, increased cutting quality, and improved performance. Laser cutting needs are based on material flow, production volume, material types, part sizes and geometries, batch sizes, and custom requirements. Robotic laser cutting can quickly produce parts with high repeatability and accuracy. Automated laser cutting solutions can be developed for 2D and 3D laser cutting and trimming.

Laser cutting robots use high-powered lasers to cut materials. The laser generates a highly focused point of heat to melt the material. Laser cutting robots are programmed with the cutting path and other specifications. Different robots are used for different applications. Common robot types are CNC machines and gantry robots. At times, a six-axis robot can be used for specialties.

CNC lasers are scalable and versatile. They are used for small to medium cutting applications on flat parts, and are limited in size. Gantry or Cartesian robots work in similar ways. They have an open structure, which makes maintenance and part replacement easier. Gantry laser robots operate with simple part geometries. They have the capability of handling larger parts, and can be configured to larger tasks.

Laser cutting can be used on a variety of metals. Laser cutting systems can be designed to meet your facility requirements and specifications. Laser cutting fixtures can help increase productivity and lower operational costs.

Sheet metal fabrication involves many variables, such as sizes and shapes, the size of the batches, differing geometries, different materials and storage options. Automated laser cutting must match your production needs.

There are some main concepts that address these categories:

Gable Manufacturing can help you determine your last cutting fixture needs.